Sample management

Release date:2025-11-10

Sample management is a crucial link in the automotive parts industry, running through the entire process of product development, quality control and production preparation.

The Importance of sample management

1.1 Sample management is the core hub connecting various links such as R&D, procurement, production and quality control, and it is a key link to ensure project success, control costs and risks. Uniformly manage samples, rationally plan the use of resources, improve work efficiency, and reduce unnecessary cost waste.

1.2 The samples are traceable. Each sample has a unique identification, which facilitates the traceability of the source information of the samples.

2 Sample Management

2.1 Account and Physical Management

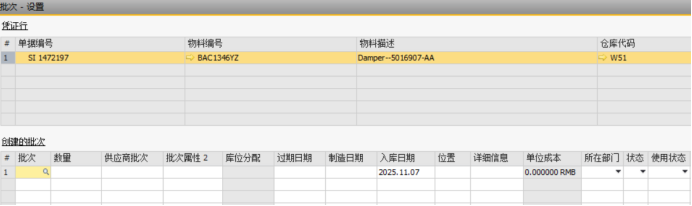

The company introduced the ERP system in 2009, discarding the traditional manual bookkeeping or electronic spreadsheet recording methods, and more comprehensively recording the full life cycle information of samples. Among them, the entire life cycle of the sample includes material number, material description, quantity information, location information, etc.

2.2 Physical Management

The core objective of physical management of samples is to maintain the integrity and traceability of samples during their preservation.

2.2.1 Acceptance and Confirmation

Upon receiving the physical samples, immediately count the quantity of the samples, check if the packaging is intact, and inspect the status of the samples for any abnormalities. After confirming that everything is correct, proceed with the warehousing process and record the basic information of the samples in the ERP system.

2.2.2 Identification

Each sample has a unique identifier to distinguish it, which should include information such as the material number and material description. In addition, the signs should be posted in a conspicuous and easily damaged position.

2.2.3 Fixed positioning

Manage the samples in separate zones: full case inventory and sporadic inventory. For this reason, the company has specially arranged sample shelves and purchased sample storage boxes to effectively manage by zones. The left area of the sample shelf stores full cases of samples, while the right area stores sporadic samples. There are area markings on the shelf for distinction.

2.2.4 Regular inventory checks and clean-ups

To ensure that the records in the ERP system match the physical items, the company conducts a comprehensive inventory check once a month on a regular basis. The main contents of inventory taking include: counting the quantity, verifying the numbers, inspecting the sample status and whether the labels are clear, etc.

To optimize sample storage resources, free up storage space and reduce the total number of samples that need to be managed, the company conducts a sample clean-up once a month, mainly to clear some expired samples and samples that have completed their missions (samples that have been tested and whose test results have been confirmed and do not need to be retained, or samples that have ended the project and will not be developed further).

3 Summary

An efficient and rigorous sample management system is the foundation for automotive enterprises to enhance R&D efficiency, ensure product quality, and control project costs, directly influencing Zhengcun's market competitiveness and brand reputation.

Last article:The informatization process of Zhengcun2025-11-07 10:18:55

Next article:Monthly nomination and evaluation for the best improvement2025-11-26 14:13:24