Improvement of rubber internal mixing process

Release date:2026-01-12

The internal mixing process is the first processing step in the rubber production process, and the internal mixing technology plays a crucial role. Rubber internal mixing refers to the process in which various constituent materials in the rubber formula are put into the internal mixing chamber through equipment such as internal mixers (kneading mills, etc.). Under the action of high pressure and high shear force, they are uniformly mixed together as the rotor rotates and the hammer applies pressure. The core secret of the intensive refining process lies in bringing the two physical processes of "blending" and "breaking up" to the extreme.

The following discusses the influencing factors of the rubber internal mixing process from the aspects of equipment and process parameters:

I. Rotor Speed

The rotational speed of the rotor, the magnitude of which directly determines the size of the shear force and the flow state of the material entering the mixing chamber.

Ii. Mixing Time

The length of the mixing time directly affects the plasticizing degree of rubber and the dispersion degree of compounding agents, and is one of the key factors determining the quality of the rubber compound.

Iii. Temperature Control

Temperature control has a significant impact on the Mooney viscosity and vulcanization reaction of rubber during the internal mixing process and is one of the very crucial control parameters for optimizing the internal mixing effect.

Take our company as an example. We have newly introduced two 55L hydraulic kneading machines, which is a prerequisite for a significant improvement in the effect of our rubber compounding process.

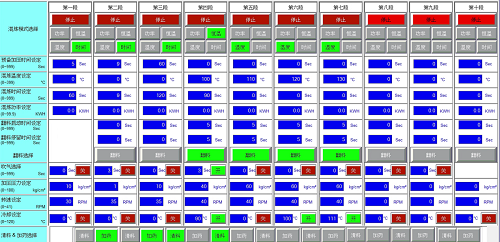

Firstly, the rotor of the internal mixer has been improved in structure, allowing the rubber compound to be stirred more evenly in the internal mixing chamber. In terms of rotor speed, it has been changed from fixed frequency to variable frequency, combined with a larger power motor and multi-stage control by control software. The rubber compound can correspond to different rotational speeds in different states to obtain more appropriate shear forces, thereby enhancing the mixing effect.

Secondly, in terms of mixing time, with the powerful cooling control system of the internal mixer (which can control the temperature at multiple points such as the mixing chamber, rotor and hammer), the use of cooling water can be controlled at any time according to process requirements. When dealing with complex and diverse types of rubber, it can also handle them with ease.

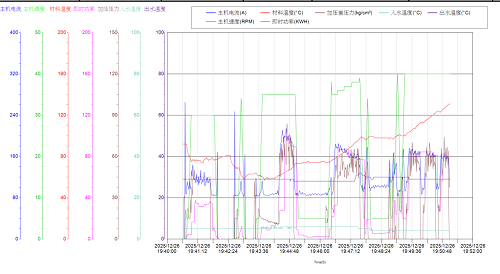

For instance, under the same discharge temperature and with good cooling effect, the rubber compound can be mixed for a longer time. In this way, both the Mooney viscosity and the dispersion degree of the rubber compound can be guaranteed.

Secondly, the new equipment is also equipped with a powerful soft control system and has added a constant temperature function. This function enables the rubber compound to be continuously mixed within a set temperature range for a certain period of time. This not only ensures the viscosity of the rubber compound but also significantly improves the relative stability between multiple batches. All these have been confirmed by our subsequent test data.

The monitoring system and reporting system of the new internal mixer have also been improved, which has greatly enhanced the control of the internal mixing process. During the mixing process, not only the temperature and current data are monitored, but also the inlet and outlet water temperatures, rotor speed and hammer pressure, etc. This can greatly help optimize the internal mixing process and continuously improve it.

In addition, the software control of the new internal mixer has also optimized the action control of the internal mixer. Thus, when using the internal mixing process, the requirements for personnel's actions are greatly reduced. With more automatic control processes, the mixing process will naturally be stable.

In conclusion, after the new equipment is put into use, the rubber internal mixing process is to bring the two physical processes of "homogenization" and "dispersion" to the extreme. Whether it is in terms of quality improvement, process stability or efficiency, significant improvements have been made, thereby enhancing the overall quality level of the company's products.

Last article:The qualities that laboratory personnel should possess2025-12-22 10:36:06

Next article:Management of front-line employees2026-01-23 11:14:24