Rubber mold cleaning methods

Release date:2025-08-26

The surface of rubber products is a replication of the mold cavity surface. Foreign substances on the mold cavity surface will all replicate onto the product surface during vulcanization, resulting in poor appearance of the product. During the vulcanization process, sulfur-containing compounds separated from the rubber compound, rust formed by the combination of moisture in the rubber compound with the metal surface of the mold, and multiple deposits of the mold release agent will all adhere to the surface of the mold cavity. These foreign substances not only affect the luster of the product surface but also cause defects such as pockmarks, scars and pits on the product surface. Therefore, the surface of the mold cavity needs to be inspected at any time and cleaned regularly. The following introduces five ways to clean molds.

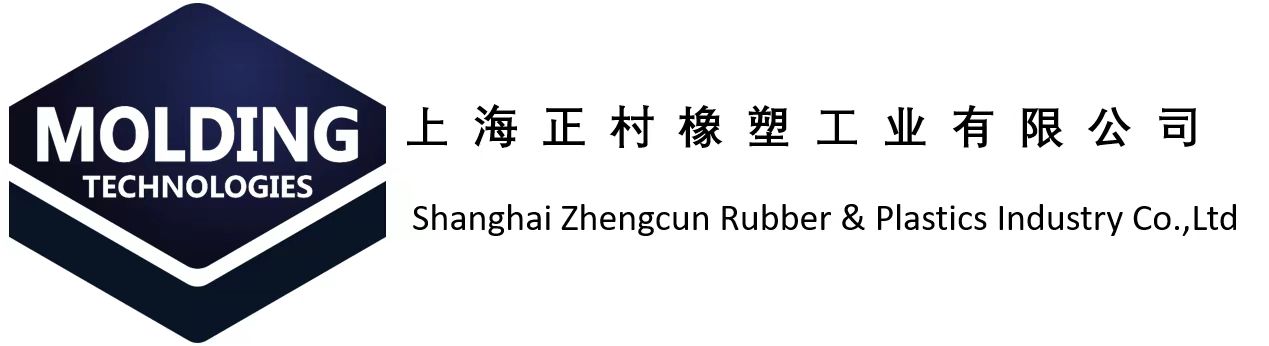

Sandblasting cleaning

Sandblasting cleaning is a process where high-speed air flow carries abrasive materials to scour the surface of the mold, and the abrasive materials' cutting action is utilized to remove the accumulated dirt. Abrasives can be glass beads and resin sand. Fruit shell powder residue, iron sand, quartz sand and plastic beads can also be used. Glass beads and resin sand have good cleaning effects and a long service life, but they cause wear and tear to molds. Sandblasting cleaning has a good effect and takes a short time, but long-term use will cause wear to the cutting edge of the mold.

Our company's sandblasting cleaning machine uses 320-mesh glass beads and 1-millimeter resin sand as abrasives. The molds are cleaned in a 1:1 ratio. Sandblasting cleaning is suitable for non-electroplated molds and has a good cleaning effect on complex structures or stubborn stains.

2 Ultrasonic cleaning

Ultrasonic cleaning utilizes alkaline solution to dissolve the dirt on the surface of molds and generates cavitation effects in the alkaline solution through high-frequency ultrasonic vibration. The dirt on the mold surface is stripped off by the shock waves produced by the rupture of tiny bubbles. Ultrasonic cleaning has a good effect, takes a long time and does no damage to the cutting edge of the mold.

Our company's ultrasonic cleaning machine uses a dedicated alkaline cleaning solution to clean the molds. Ultrasonic cleaning is suitable for flat vulcanization molds.

3. Dry ice cleaning

Dry ice cleaning involves the high-speed impact of solid dry ice particles on the surface of the mold cavity driven by compressed air. Under extremely cold conditions, the surface dirt layer rapidly becomes brittle and cracks. At the same time, the crushed dry ice particles enter the cracks, and their volume instantly expands by 800 times, quickly peeling off the dirt layer, thereby achieving the cleaning effect. Dry ice cleaning of molds can be carried out simply by lowering the temperature to around 80 degrees Celsius. It can be done online (online cleaning is suitable for local temporary cleaning and is not thorough enough). Dry ice can be stored in a dedicated dry ice box for 3 to 5 days. The cleaning effect of dry ice is average, the time is short, and it does no damage to the cutting edge of the mold.

Our company's dry ice cleaning machine is mainly used to clean stubborn stains on the surface of electroplated molds.

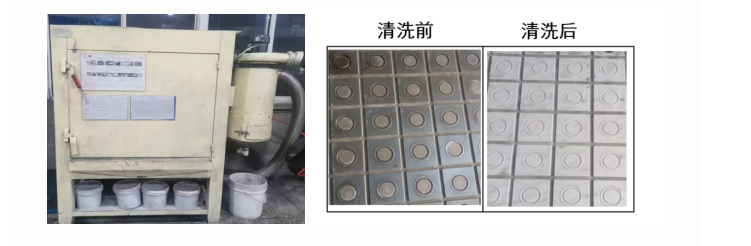

4 Laser cleaning

Laser cleaning uses high-frequency short-pulse lasers as the working medium. High-energy beams of specific wavelengths are absorbed by rust layers, paint layers, and contamination layers, forming rapidly expanding plasma (highly ionized unstable gas), and simultaneously generating shock waves. These shock waves break down contaminants into fragments and remove them, thereby achieving the cleaning effect. Laser cleaning has a good effect, takes a short time and causes no damage to the cutting edge of the mold. Laser cleaning has dead corners. Areas that the light cannot reach cannot be cleaned. Our company's laser cleaning machine is mainly used for cleaning molds with simple structures.

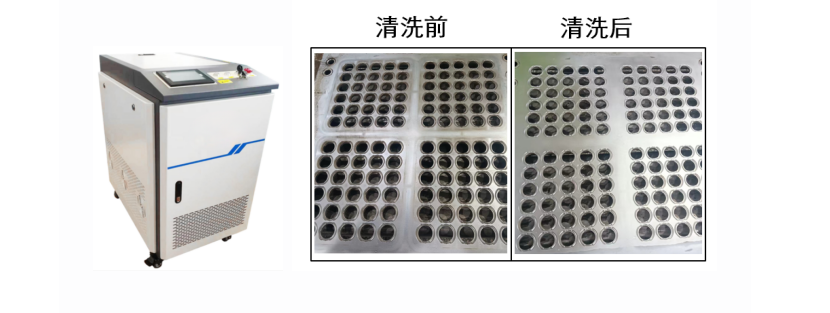

5. Alkali washing

Alkali washing, as a traditional chemical cleaning method, mainly targets electroplated molds and must strictly follow the following steps:

5.1 Preheating treatment: Preheat the mold to 200 degrees to make the scale carbonized and loose (insufficient temperature will make it difficult for the cleaning agent to penetrate).

5.2 Original solution rinsing: Spray the surface of the mold with the original solution to dissolve and peel off the scale.

5.3 Mechanical assistance: Use a copper brush to remove obvious stains. For stubborn residues, a bamboo scraper can be used to assist in removal.

5.4 Neutralization Rinse: Use clean water to rinse off surface stains and alkaline solution;

5.5 Drying and curing: After the moisture is blown off with compressed air, apply anti-rust oil immediately.

Alkali washing is mainly aimed at electroplated molds. It has a good cleaning effect, takes a short time and causes no damage to the molds.

A clean mold is a guarantee of product quality. Mold cleaning is not limited to one cleaning method. For example, the mold of a flat vulcanizing machine can be cleaned first with a laser cleaning machine, and then with sandblasting cleaning (try to reduce the time and frequency of sandblasting cleaning). It can also be cleaned first with a dry ice cleaner and then with an alkaline one. Mold cleaning not only needs to ensure the mold is clean but also take into account its service life. Therefore, finding and determining the best cleaning method for each mold is the goal and task that Bao Quan has always pursued.

Last article:In the south of the colorful clouds, our hearts are filled with shared memories2025-08-11 10:43:42

Next article:Feelings after entering Zhengcun ----" Three "likes2025-09-18 23:15:27