Equipment upgrade - Brand new internal mixers and open mills

Release date:2025-07-29

Under the development concept of continuous improvement, our company has comprehensively upgraded the mixing equipment in the material laboratory and the rubber compounding workshop. This upgrade is quite significant. The newly introduced internal mixers and open mills have achieved remarkable improvements in intelligence, error-proofing capabilities and stability.

Production equipment is an important hardware guarantee for productivity, and its stable operation directly affects product quality and production efficiency. In the production of rubber products, rubber compounding, as the most advanced process, the mixed rubber produced plays a decisive role in the subsequent processing and the quality of the final product. The quality of mixed rubber not only depends on the formula but also on the mixing process. The core guarantee of this process is the equipment, so the importance of the equipment is self-evident.

The purpose of equipment upgrade

This upgrade simultaneously replaced the rubber compounding test equipment and the mass production equipment. Replacing laboratory equipment is to ensure that the physical properties and processability of the experimental formula are reliably verified, making the experimental data more genuine and accurate. Replacing the experimental equipment with the mass production equipment simultaneously can minimize the performance differences when the experimental formula is scaled up to the mass production formula, providing a solid foundation for stable production.

2. Advantages of the new equipment

2.1 Experimental Equipment

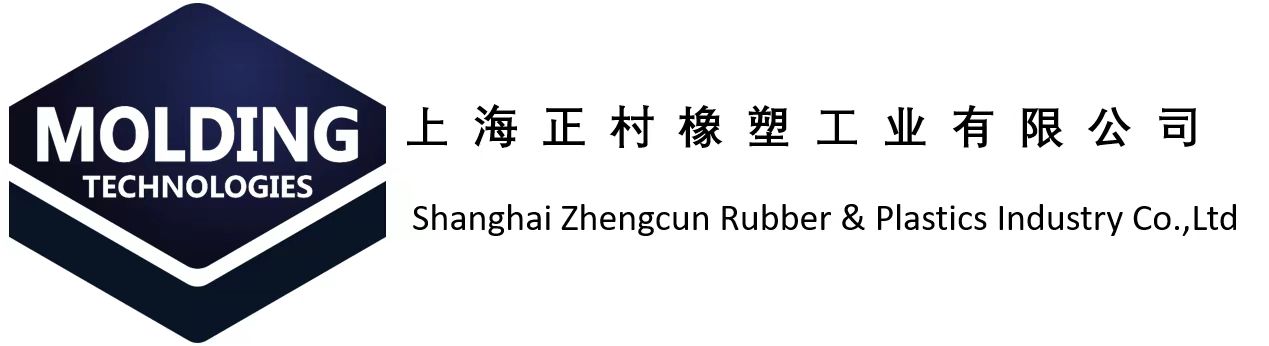

Small internal mixer

The small internal mixer is equipped with a fully automatic mixing system. With mixing time, temperature and power as control conditions, it can set 10 mixing process steps. With the help of variable-frequency motors, the rotor speed at each step can be adjusted and controlled, enabling the material to find the best mixing process. Every step of the entire mixing process is under monitoring. Any abnormality will trigger an alarm in a timely manner, and all data can be recorded and stored, ensuring full traceability throughout the process.

In addition, the mixing tank and the stirring shaft are made of high-wear-resistant materials at the tip, which enhances the mixing and shearing effect. The combination of high-power motors and heavy-load frequency converters further enhances the reliability of equipment usage.

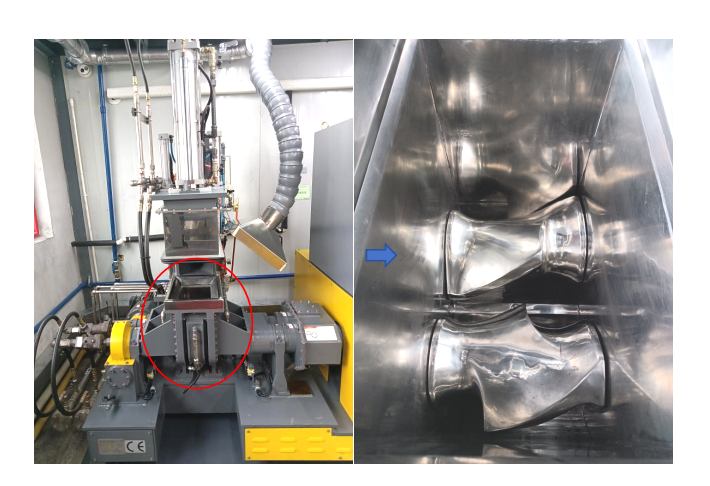

Small open mill

The safety of open grinding operations is of vital importance. The new equipment has been equipped with safety light curtains for this purpose, with up to 9 sensors on each side. If hands exceed the safe range during operation, the equipment will automatically sense and immediately stop, fully ensuring the personal safety of the operators. Functionally, the dispersibility of the open mill rubber compound mainly depends on the thickness of the thin pass. The minimum roller distance of the new open mill can be adjusted to 0.1mm, ensuring that each batch of rubber compound can be fully dispersed.

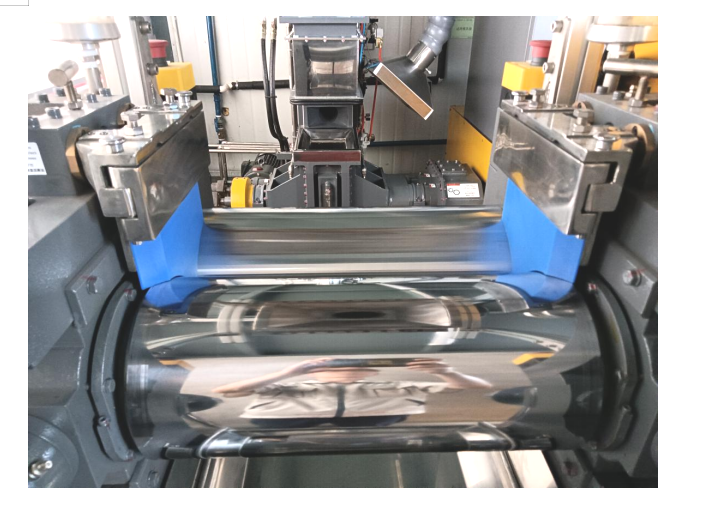

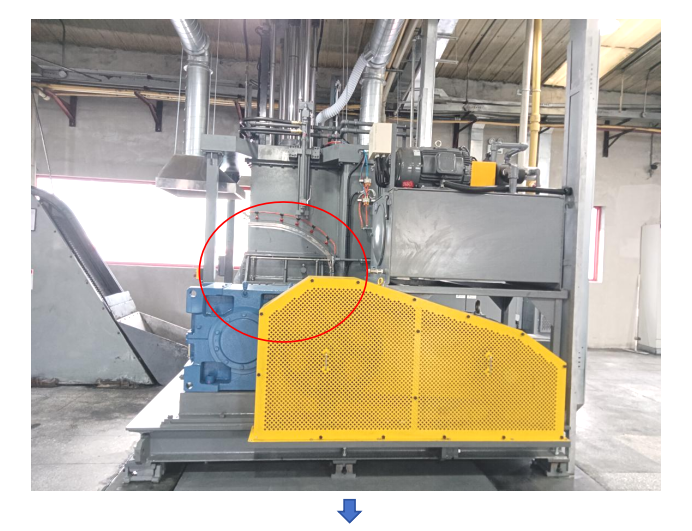

2.2 Mass production equipment

Large internal mixer

The large internal mixer for production can be regarded as an enlarged version of the small internal mixer in the laboratory. Besides having the above-mentioned functions of the small internal mixer, it has also undergone multiple upgrades. The drive mode of the top plug has been upgraded to hydraulic drive, with pressure adjustable steplessly. It features high precision and high strength, and can achieve constant pressure control. The stirring blades have been enlarged, resulting in a stronger overall shearing effect and more uniform dispersion of the rubber compound. Meanwhile, the equipment is equipped with a feeding scanning code error-proofing system, which can precisely deliver materials in each process step during the fully automatic mixing process. The sealing performance of the equipment has also been improved. Fixed dust covers are adopted, which not only enhances the workshop environment but also reduces material waste.

This comprehensive upgrade of the rubber compounding equipment is an important measure for our company to deeply cultivate production optimization and pursue excellent quality. These upgrades will drive the quality of the mixed rubber to a new level, provide reliable guarantees for the subsequent processing procedures, and help the company achieve breakthroughs in product competitiveness and production efficiency. We look forward to it.

Last article:Continuous improvement - Automated improvement2025-06-30 13:09:08

Next article:In the south of the colorful clouds, our hearts are filled with shared memories2025-08-11 10:43:42