Continuous improvement - Automated improvement

Release date:2025-06-30

Under the sweeping wave of technology, the manufacturing industry, as the foundation of the real economy, is faced with both opportunities and challenges. The rising labor costs, intensified market competition, and customers' strict requirements for quality and delivery time have gradually made the traditional manufacturing model a constraint on the development of enterprises. For the manufacturing industry, continuous improvement is the key to sustained competition, and the improvement of manufacturing site automation is the core path for enterprises to reduce costs, increase efficiency and enhance competitiveness. Shanghai Zhengcun Rubber and Plastic Industry Co., Ltd. has keenly perceived the trend, directly faced its own pain points, and taken automation improvement as a tool to break through and seek innovation.

1. Enterprise pain point: Development obstruction under the traditional model

In the operation of our Zhengcun Rubber and Plastic Company, we are also trapped by multiple problems:

1.1 The Dilemma of Human dependence

The proportion of manual operation is high, the efficiency is low and the cost keeps rising. A large amount of human resources are invested in traditional production processes, which not only slows down the production pace but also, with the rising labor costs, increases the operational burden on enterprises and squeezes their profit margins.

1.2 Fatigue and Quality Concerns

Workers who do repetitive and monotonous labor for a long time are prone to fatigue. Take inspectors as an example. The hourly output is limited. As the working hours increase, the error rate rises simultaneously. The risk of defective and abnormal products flowing out sharply increases, damaging the reputation of product quality and affecting customers' willingness to cooperate.

1.3 Prominent safety hazards

Long hours of high-intensity physical labor breed unsafe behaviors among workers. Once a safety accident occurs, it not only causes personal injury, but also brings economic losses and image damage to the enterprise, disrupts the production order and undermines the social trust of the enterprise.

Facing this, the Manufacturing Department, the Technology Department and the Security Department worked in coordination, delved into the site to explore solutions, promoted the improvement of semi-automation and automation, and reshaped the production pattern with technological innovation

2. Semi-automation improvement: Performance Breakthrough in the transition stage

Semi-automation is the ladder towards full automation, integrating the advantages of manual labor and automated equipment, avoiding the large investment risks of full automation, and making up for the shortcomings of manual production.

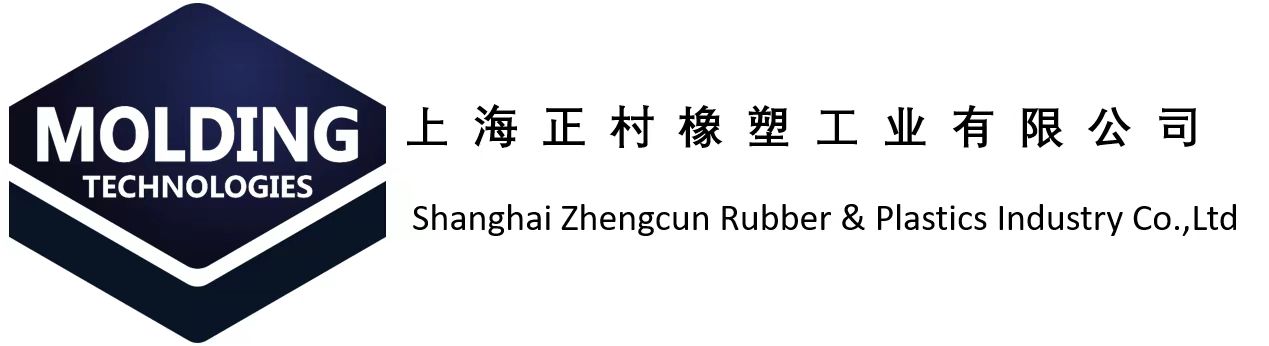

2.1 Casing Assembly Machine: From "Manual Pressing" to "Automatic Jacking"

Before improvement: The two types of shock-absorbing pad products required the assembly of metal sleeves inside. The sleeves were manually placed and the products were pushed in by hand. Long-term hand pressing led to high labor intensity, low efficiency, and increased risk of hand injuries. It was not only tiring but also restricted production capacity. The risk of work-related injuries also affected the stability of employees.

After improvement: The sleeve slots were made of PE plates, and the ejection device was fabricated in combination with components such as cylinders. Workers only need to place the products and sleeves in the corresponding positions, press the button, and the cylinder will operate to push the sleeves in. The design of the two-hand start button builds a solid safety line. This renovation has significantly reduced the labor intensity. The increase in production capacity is visible to the naked eye. Employees' operations have become easier, the risk of work-related injuries has been eliminated, and the continuity and stability of production have been enhanced.

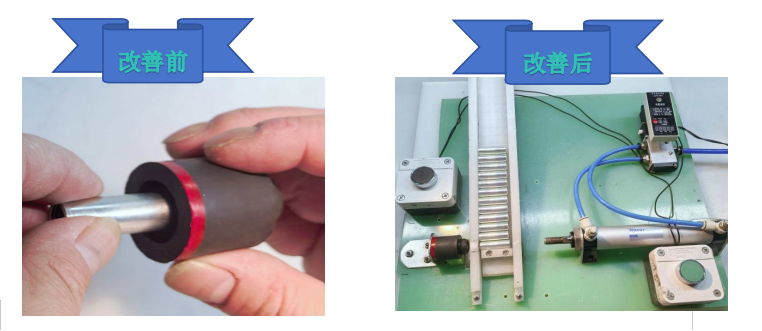

2.2 Aluminum Parts Grinding Machine: "Intelligent Upgrade" for Flash Removal

Before improvement: After the two aluminum parts were coated with rubber and formed, the flash at the junction needed to be manually scraped off with a tool and then sandblasted. Manual operation is inefficient, flash is difficult to remove completely, and tools are prone to scratching hands. Unstable quality and safety risks coexist. Defective products affect downstream processes, and work-related injuries also increase the enterprise's post-accident costs.

After improvement: The electric motor works in coordination with the slide rail, the product is fixed in the slot, the motor moves back and forth, and the sandpaper grinds the edge, quickly and thoroughly removing burrs and eliminating potential safety hazards. Production efficiency has soared, product quality is uniform, employees are protected from knife injuries, the production process is smoother, and a solid quality foundation is laid for subsequent links.

3. Automation Improvement: A Qualitative and Efficiency Leap in Advanced Transformation

Automation improvement is a high-level form of production upgrading. It introduces advanced technical equipment to drive highly automated and intelligent production and reshape the manufacturing process.

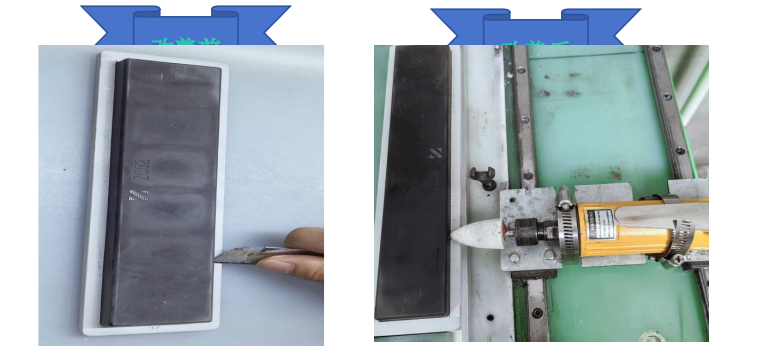

3.1 Automatic Machine Edge Trimming Machine: The "Efficiency Revolution" in Rough Edge Treatment

Before improvement: After the shock-absorbing pad products were formed, there were burrs. The edges were trimmed one by one manually with scissors, which was extremely inefficient, averaging 2 minutes per piece, and the damage rate of the products exceeded 3%. Low efficiency and high defect rate slow down the delivery cycle, increase the cost of defective products, and weaken the competitiveness of enterprises in taking orders.

After improvement: Contact a professional manufacturer to customize an edge trimming machine. Personnel only need to pour the product into the vibrating disc, and the machine will automatically feed and trim the edge. The edge trimming efficiency has increased by more than 70%, and the defect rate of trimming has dropped to about 1%. The delivery cycle is compressed, costs are reduced, and product quality is stable, which helps enterprises take on more orders and expand market space.

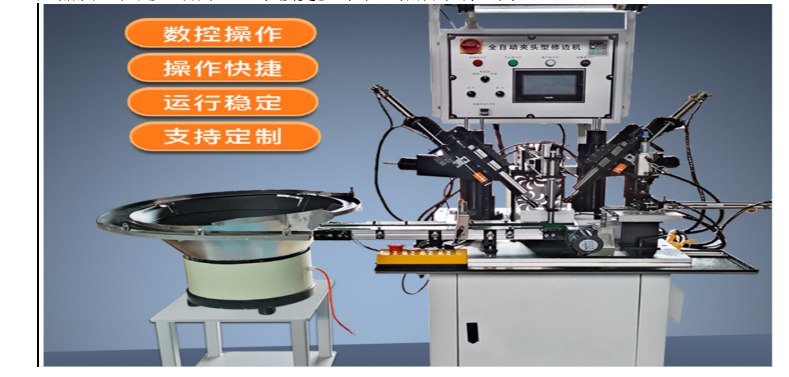

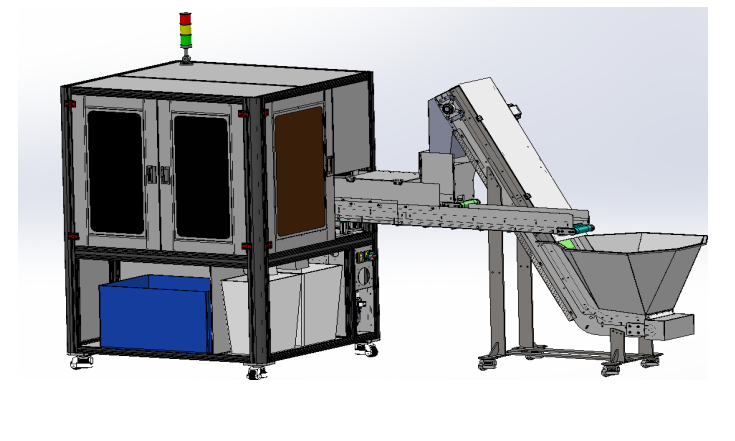

3.2 Visual Inspection Machine: The "Intelligent Eye" for Quality Inspection

Before improvement: The stability and consistency of rubber parts were poor. To ensure quality, all our products underwent full inspection, even 200% full inspection, which led to high labor costs. Especially for over 30% of small products (with a diameter of ≤5CM), the human eye can inspect 1,000 pieces per hour. The quality is hard to stabilize. Personnel fluctuations can also lead to misjudgment and missed inspections, with a high risk of defective products being released and a large hidden danger of customer complaints.

After improvement: Seek out automated inspection manufacturers through the Internet and exhibitions. After research, customize visual inspection equipment suitable for small products. Use AI technology to classify, identify and screen qualified and unqualified products. Efficiency has soared by 400%, and adverse outflows have been basically eliminated. Labor costs have been significantly reduced, quality control has been precise, customer satisfaction has improved, and the company's reputation for quality has been consolidated.

4 Outlook: The long-term value of Automation improvement and Industry Resonance

The improvement of automation in manufacturing sites is a gradual journey. Semi-automated and automated equipment, in the continuous improvement of our Zhengcun rubber and plastic production, has broken the shackles of the traditional model, achieving cost reduction (labor, defective costs), efficiency increase (production efficiency), quality improvement (product quality), and excellence (safety, reputation).

In the future, technological iteration will drive the deepening of automation improvement and expand more possibilities for manufacturing. We look forward to more manufacturing enterprises embracing automation, forging ahead in the wave of intelligent manufacturing, and soaring in the global market with technological innovation as their wings, injecting vigorous impetus into the high-quality development of the manufacturing industry and jointly painting a new picture of industrial upgrading.

Last article:Create a lean site and enjoy a quality life to the fullest2025-06-18 22:51:39

Next article:Equipment upgrade - Brand new internal mixers and open mills2025-07-29 09:51:12