The construction of the production mode of Zhengcun

Release date:2024-05-07

ZPS (ZhengCun Production System) is a kind of production method of Zhengcun, which is optimized and improved on the basis of TPS (Toyota production system) and is more suitable for Zhengcun.

As we all know, TPS is a major breakthrough from the Fort-style production method that once dominated the global industry and has had a profound impact around the world. However, each enterprise has its own different characteristics, and TPS is not completely suitable for all enterprises. Therefore, Masamura constantly introduced various concepts in TPS while cooperating with Toyota, taking the essence and eliminating the dross, and proposed the ZPS concept.

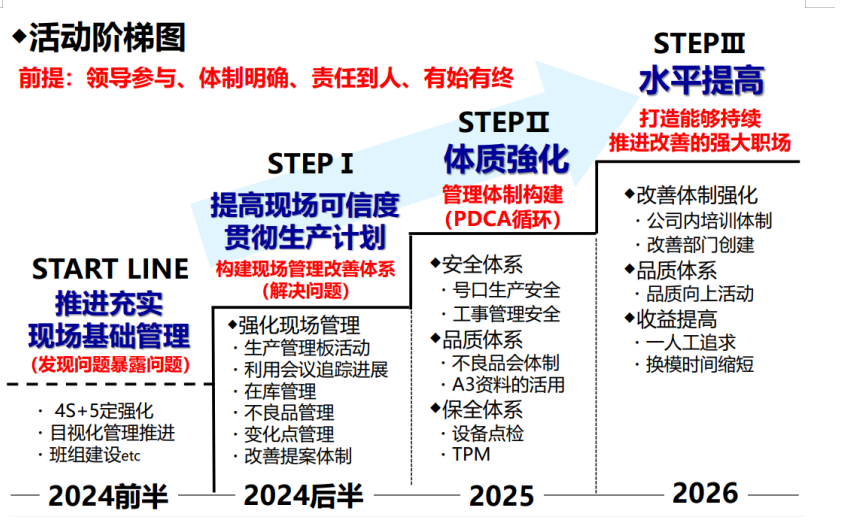

Based on the current situation of Masamura and Toyota's TPS concept, the following activity ladder chart is developed under the premise of leadership participation, clear system, responsibility to the person, and completion:

At present, a lot of work on START LINE and STEP1 is in full swing, specifically:

1 4S5 idine

After a long period of publicity and rectification, the on-site 4S5 determination work has achieved certain results. From the most basic finishing to the fixed positioning of items, the boxes used in the workshop are distinguished by color, green boxes are placed for good products, red boxes are placed for bad products, yellow boxes are placed for goods to be determined, and black boxes are placed for waste edges.

2 Visual management

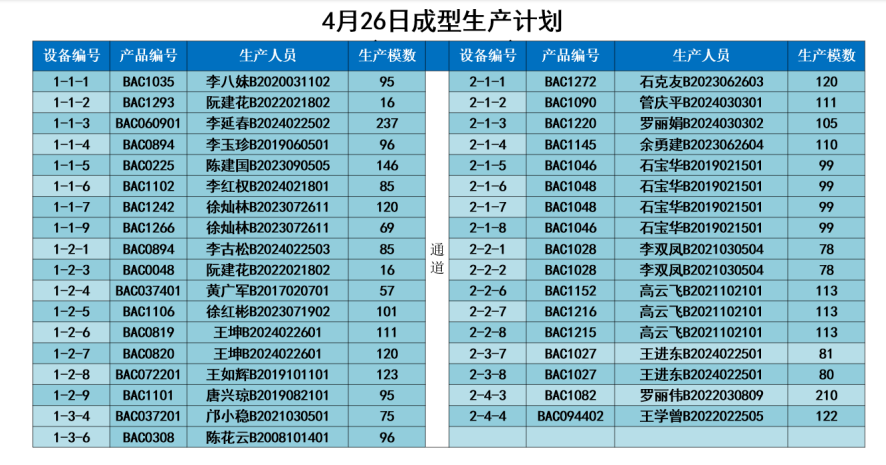

2.1 Production plan bulletin board

The planning board shows the production plan data of the day, specific to what time and what process to produce what products; Who produces what products on which equipment, and the planned quantity, so that field operators know their production tasks at a glance. At the same time, managers can also understand the field work content.

2.2 Production schedule bulletin board

A production schedule board is installed on each device, showing the planned module, the required module and the actual module. Let operators and workshop managers know the progress in time, find anomalies, and deal with them in time.

3 team construction

Team management is an important part of the site management, the main five tasks of management.

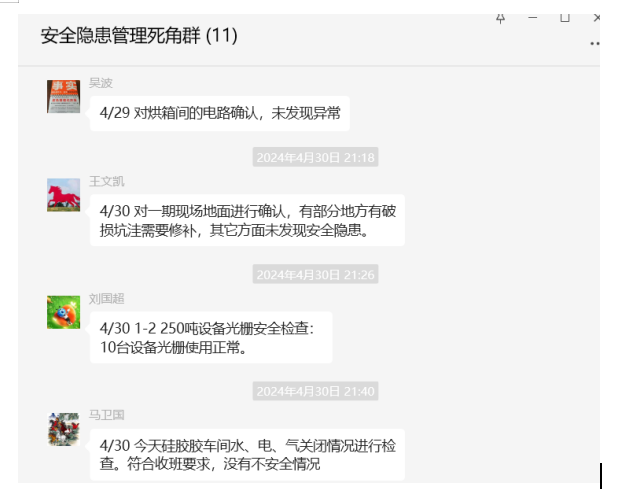

3.1 Security

3.1.1 The production team of the manufacturing department will conduct safety education and training before work every day. At the same time, the company will establish a safety management dead end group, and relevant departments will check and correct themselves every day to identify hidden dangers and take countermeasures in time to minimize safety risks.

3.1.2 The Company shall, in accordance with the occupational health requirements, take measures for the prevention of occupational diseases and organize employees to undergo occupational disease physical examination on a regular basis.

3.2 Quality

Each process has the self-inspection of the production team leader of the process and the inspection of the process inspector, the first time to find and control the abnormal, the defective products are isolated in time, so that "no defective products are accepted, no defective products are produced, and no defective products are released".

3.3 Production

Achieve just-in-time production and ensure that production plans are achieved.

3.4 Devices

Make basic maintenance of the equipment by the front line management of the manufacturing department to ensure the normal operation of the equipment.

3.5 Cost

Grasp the unit use of materials, do not produce a lot of production, so that the cost is decreasing.

4 Production management board activities

4.1 The manufacturing department will establish a production management Kanban in the production workshop, collect the production data of each process and each production equipment, and display it together with an electronic board. Simply put, it is the production information Kanban, which everyone can see and understand the production information in time.

4.2 The previous process can see the production demand of the next process in time at the current time, and corresponding to the time.

5 Use meetings to track progress

At present, all departments have daily meetings, which are used to deal with every specific matter in daily life. There are daily production meetings to discuss and deal with the anomalies that occur on the site that day, and throw them into the corresponding anomaly group, the group owner is responsible for tracking and processing, and the monthly meeting is resumed again. There are TOP10/30 monthly meetings for reporting and tracking cost improvement results.

6 Manage the library

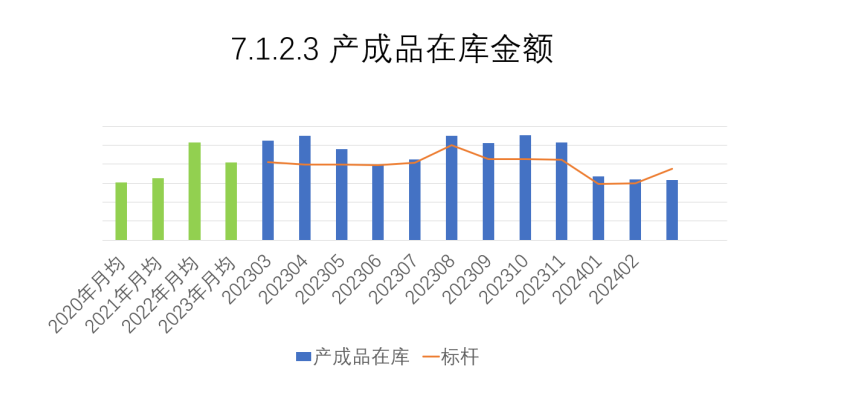

6.1 Amount in storage

Inventory is the "root of all evil." Track the inventory amount every month, implement the production according to order, small single production, and try to minimize the inventory.

6.2 Inactive inventory

List the details of idle inventory, find out the reasons and responsible persons, review and propose disposal plans at the monthly uncleared meeting.

7 Management of defective products

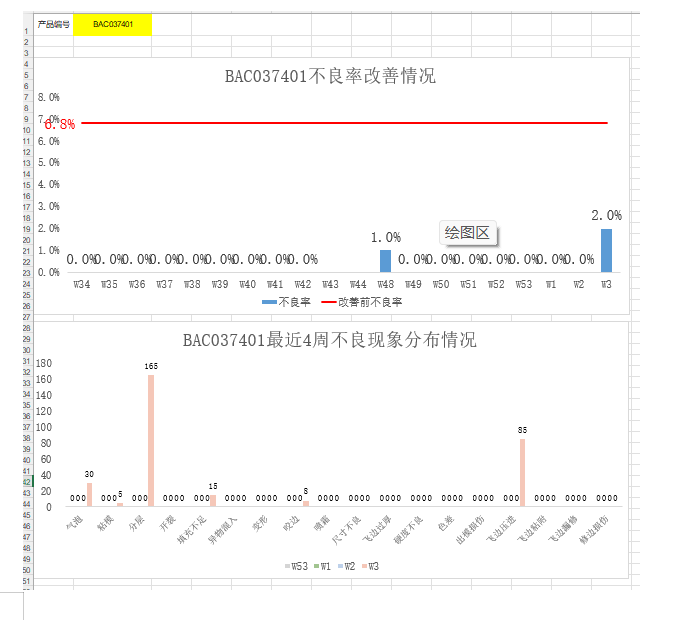

Molding design engineers are divided into four groups, each of whom tracks a group of products, collects the defective products produced on duty, analyzes the causes of the defective products, finds the main causes of the defective products and gives countermeasures to reduce the defective rate of products.

8. Improve the proposal system

8.1 Two trapped one proposal

In order to let managers work without questions and have good ideas to give timely feedback, the company carried out two difficulties and one proposal (difficulties, confusion and proposals) activities, which were proposed by various departments in the department group and answered by the department head.

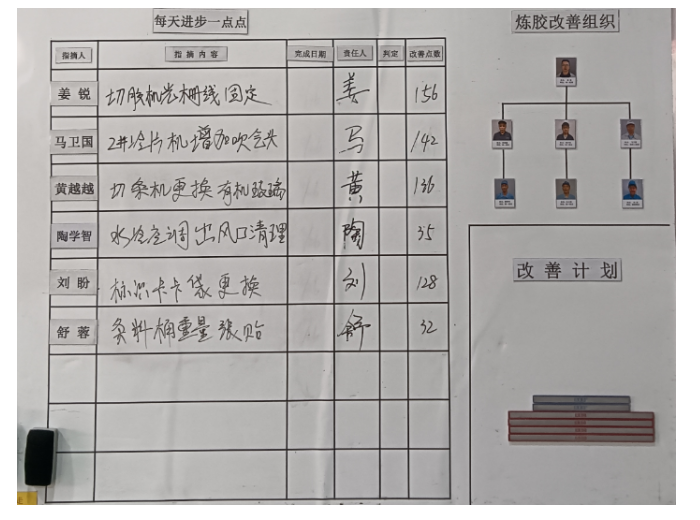

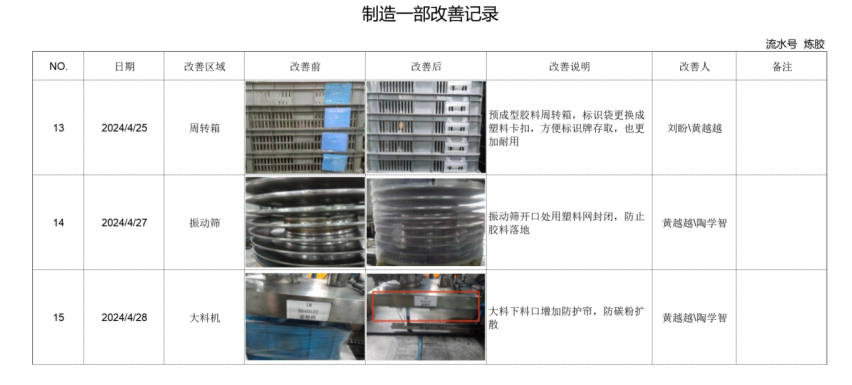

8.2 Make a little progress each day

Production departments actively carry out improvement proposals, and record them after implementation to form improvement records.

At present, Zhengcun is still in the stage of START LINE and STEP1, and the basic management of the site is still weak. It is necessary to systematically promote the system of 4S5 identification, visual management, team construction and improvement proposal activities, build a system that can expose abnormalities, cultivate talents who can improve the site and things, and finally build a culture that regards the above matters as virtues. Under the leadership of the company's management, it is believed that in the near future, Zhengcun will definitely form a ZPS system with characteristics.

Last article:How to Be a Department Manager (201909 edition)2024-04-29 15:02:27

Next article:Comprehensive budget management helps enterprises develop2024-05-21 11:16:05