New opportunities - Application and prospect of liquid silica gel

Release date:2023-11-20

Liquid silica gel, also known as liquid silica gel, is referred to as LSR (Liquid Silicone Rubber), because of its low molecular weight, it is a viscous liquid state at room temperature. Liquid silica gel has excellent high resistance, low temperature performance, high elasticity, good electrical performance, non-toxic environmental protection and other characteristics, suitable for automotive, food, electronic appliances and other fields.

1 Advantages of liquid silicone

1.1 Completely non-toxic and tasteless, more environmentally friendly. Liquid silica gel has simple composition, adopts platinum catalytic vulcanization system, is safe and odorless, VOC content is very low, and can meet food grade requirements.

1.2 Excellent optical performance. Liquid silica gel does not yellowing, low dispersion, high light transmittance, after experiencing high temperature aging light transmittance can still reach more than 95%.

1.3 The shape of the finished product is stable. Liquid silica gel is in a flowing state before vulcanization, and the molding temperature is low, so the shrinkage rate after molding is small, no secondary sulfur, no secondary dimensional shrinkage.

1.4 High degree of automation, more stable quality. Liquid silicone does not need mixing, simple post-treatment, and less manual intervention in the entire production process from raw materials to finished products.

2 Application of liquid silica gel

2.1 Automobile Industry

Liquid silica gel has good electrical insulation and elastic properties, so that it is widely used in automotive circuit systems, electrical components sealing, its excellent optical properties also make it in the lights and other optical components are used.

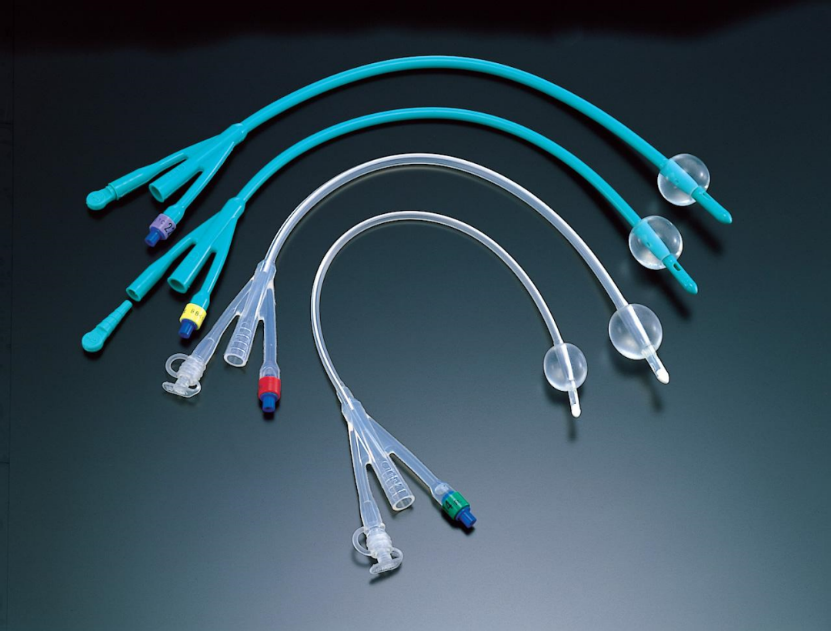

2.2 Medical Industry

Its safety, environmental protection, non-toxic and tasteless characteristics make it widely used in the field of respiratory equipment and human body contact.

2.3 Electronics Industry

As a kind of insulating hydrophobic material, liquid silica gel is widely used in the field of consumer electronics, and its application in electronic components and high-end electrical equipment is also more extensive. In addition, its low viscosity and forming temperature also make it used in the potting of electronic components.

3 Prospects of liquid silica gel

With the development of society, the requirements of various industries for basic materials have gradually increased, and liquid silicone has also developed towards higher performance and a wider range of fields.

3.1 Higher environmental requirements. Environmental protection requirements continue to improve, which has more stringent requirements for the substrate selection, synthesis and additives of liquid silicone.

3.2 Higher performance requirements. With the expansion of the application field and the improvement of the function of the host, it is required to have a wider use temperature range, higher mechanical properties, and at the same time for special fields, it should also have specific properties, such as thermal management performance, better electrical performance, higher light transmission performance.

3.3 Self-lubricating. If you can meet the requirements of self-lubrication without affecting the performance, meet the installation and use effect of low hardness products.

3.4 Microinjection. For more sophisticated parts, equipment, molds and even the material itself need to be continuously optimized to achieve milligram injection.

4 Zhengcun liquid silicone project process

In order to achieve the vision of "by providing competitive products, becoming a model of the industry and a first-class supplier of the global supply chain, making due contributions to China's polymer products industry", our company has launched the liquid silicone project, which plans to cover an area of 1500 square meters, and introduces 6 advanced liquid silicone injection machines such as Germany's Aberg. The first phase of construction is expected to be completed and put into operation in March 2024. After the completion of the project, our company can realize the automatic production of liquid silicone injection.

All along, Zhengcun has taken scientific and technological progress and quality control as the top priority of enterprise development. We continue to improve, excellence, will lead the development of the industry!

Last article:Product design thinking2023-11-09 09:29:38

Next article:Environmental improvement workshop toilet renovation2023-12-04 09:46:34