Japan TPS Lean Training Journey

Release date:2023-09-25

As is well known, Toyota in Japan has become one of the most profitable companies in the world with its undisputed strong competitiveness, maintaining impressive performance in terms of profits. With Toyota's high performance growth, companies around the world are learning from the Toyota Production System, drawing on and learning from successful experiences. Masamura has been introducing TPS for many years, inviting Toyota experts to provide on-site guidance and organizing employees to participate in lean training in Japan multiple times.

In September 2023, under the organization of the company, the new phase of the Japan Lean Training Journey set sail again. This time, a total of 14 colleagues were invited to experience the authentic TPS in Japan.

Day 1 of Training: TPS Overview Study

In the years of investment in TPS in the company, although we have gained a certain understanding of TPS, in the process of in-depth introduction and explanation by the teacher, our understanding of some aspects is still limited. Only by thoroughly understanding and gradually applying it to practice can we achieve better results.

TPS is a combination of JIT and automation as the two core pillars, combined with 5S, TPM, visual management, standardized operations, etc., to continuously create more value for enterprises.

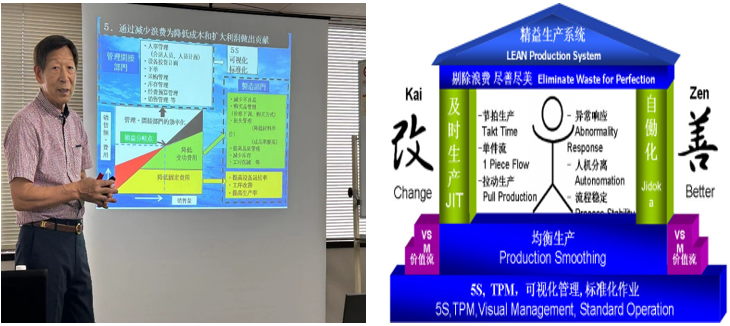

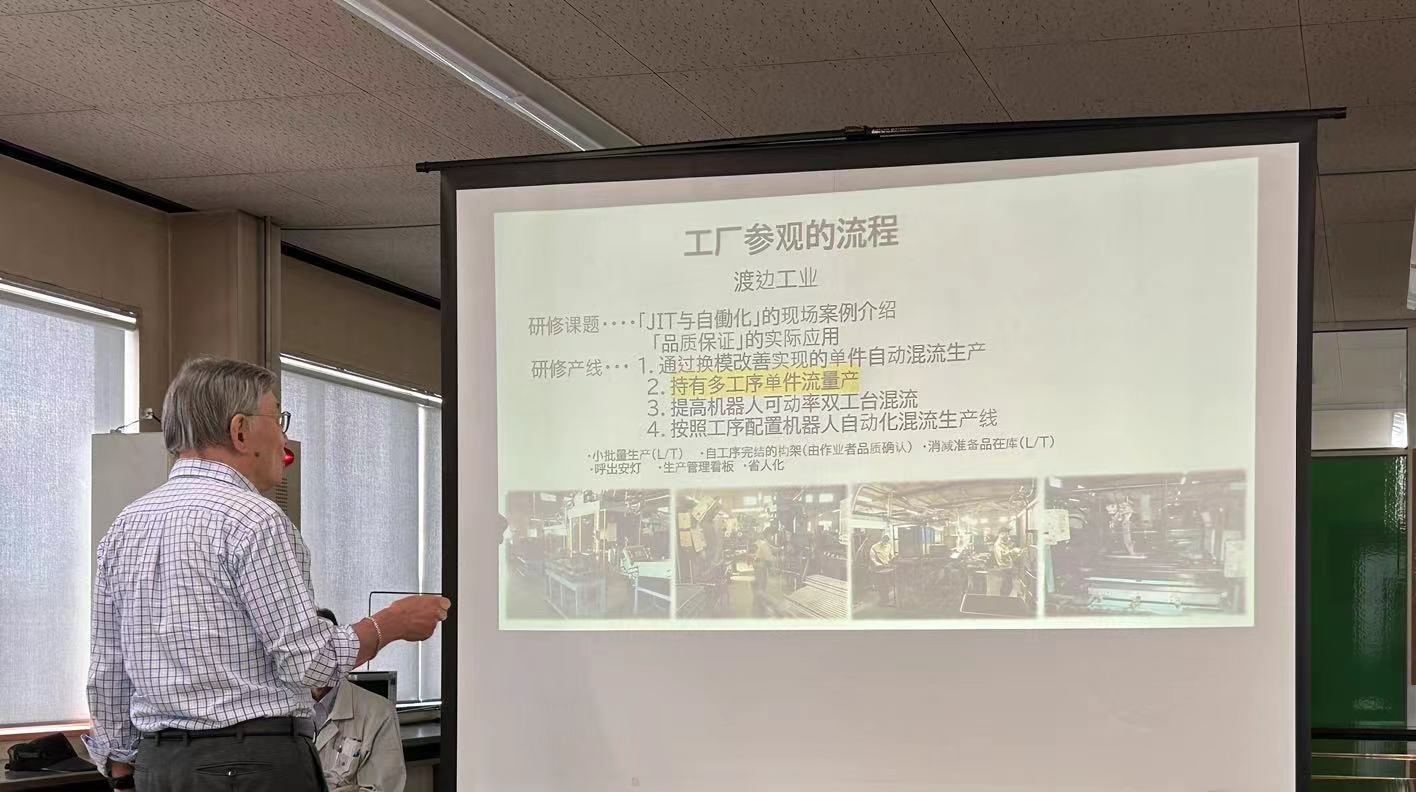

Day 2 of Training: Watanabe Industry and Nijin Visits

As a metal parts machining enterprise, Watanabe Industry, although not very large in scale and not very advanced in equipment, has impressive on-site 5S and signage management.

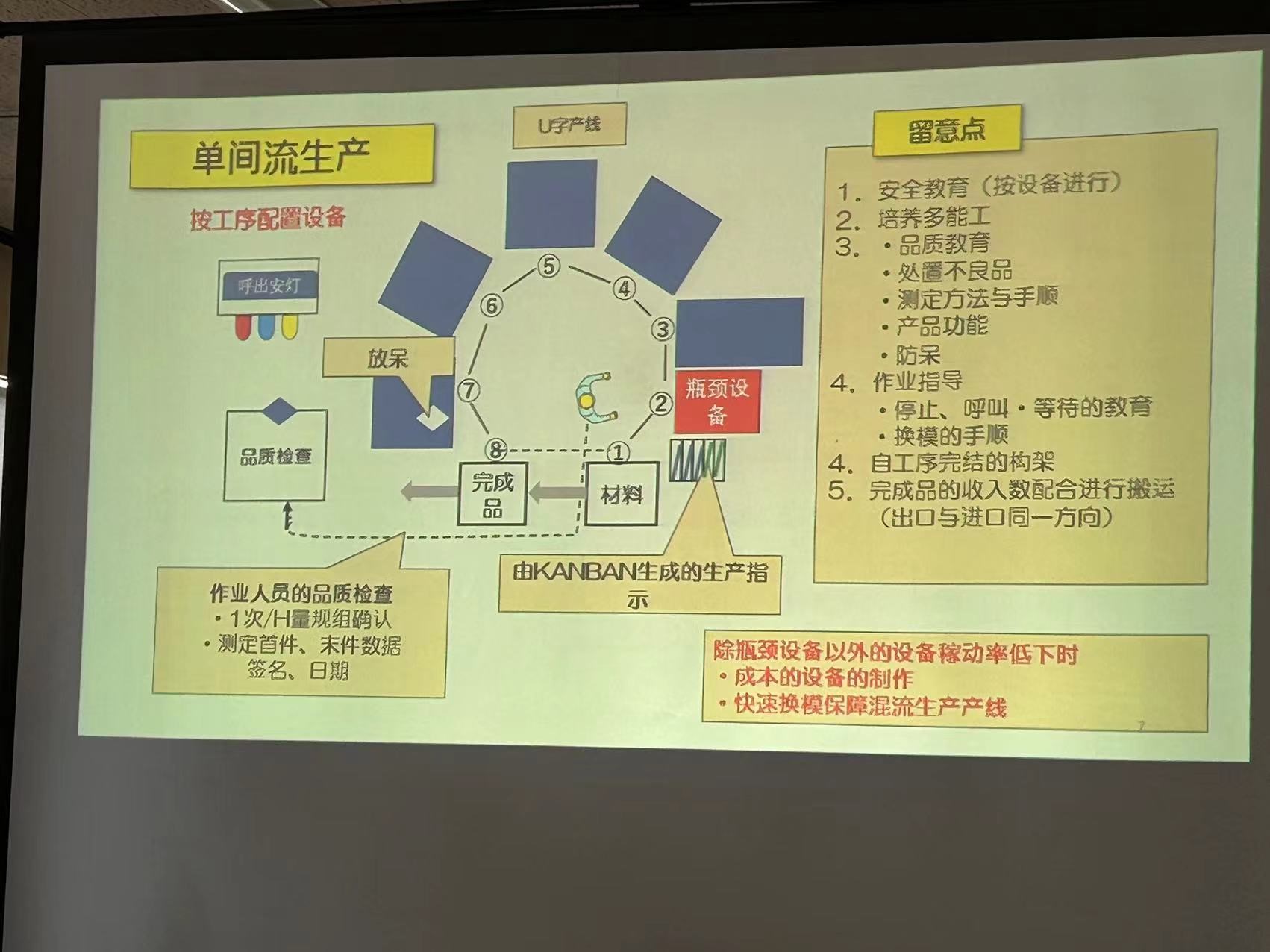

At the workshop site, I had a close experience of the flow production mode of U-shaped workstation layout and the application of versatile workers. From materials to various processes to finished products, the layout was counterclockwise, and all processes were completed by one operator, greatly improving production efficiency.

At the workshop site, I had a close experience of the flow production mode of U-shaped workstation layout and the application of versatile workers. From materials to various processes to finished products, the layout was counterclockwise, and all processes were completed by one operator, greatly improving production efficiency.

The operators conduct self inspection on the completed products and conduct spot checks on one product per hour, without setting up a dedicated full inspection process to reduce unnecessary waste.

By importing and optimizing rapid mold changes, small batch production can be achieved.

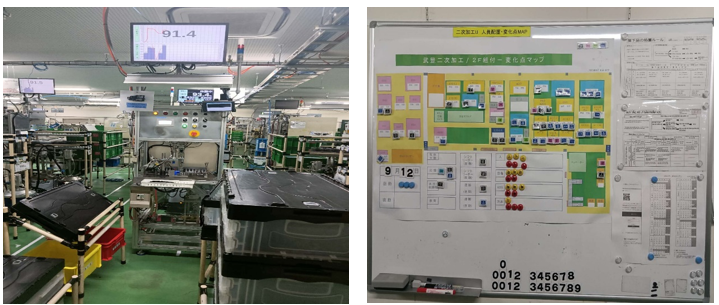

The Rijin Industrial Wufeng Factory visited in the afternoon is an intelligent chemical factory established through automation equipment and Internet of Things technology. Domestic and foreign companies and factories use independently developed MCM systems to create digital management, and display various types of data through electronic signage.

Equipped with monitors at each work station, the efficiency and production progress of the station can be clearly understood. The production rhythm of each station can be displayed on a large display next to it, which can reflect abnormalities in a timely manner.

When an employee encounters an abnormal request, they immediately stop - call their superiors - and wait. The purpose of doing so is also to interrupt the continuous production of defective products. After the call, the workstation call is displayed in different colors on the large display according to the type of abnormality, and the timer is started. The on-site personnel can learn from the large display which abnormalities and which ones have not been resolved yet.

Day 3 of training: Visit to Kato Studio

Gain a deep understanding of the circulation and application of kanban in various processes at the training workshop of Kato Manufacturing Institute (the demand kanban only flows between the previous process) and pull production (producing the necessary output at the necessary speed).

Through on-site practice, we have gained a deeper understanding of the waste of waiting, handling, and bottleneck processes, and have also given us inspiration to eliminate these on-site waste. At the same time, it is emphasized that improvement must be targeted, set goals, and supported by actual data.

The fourth day: TPM learning

TPM, as a full-time production guarantee, is not only a matter of safeguarding a department, but also a task that all employees need to participate in. Improve productivity by eliminating and improving activities that lead to equipment failures, shutdowns, or performance degradation. Doing a good job in TPM can provide reliable support for the development of TPS.

The visualization of the status of preservation tools can greatly save us the time to search for tools and judge their status, which is also a way to eliminate waste. It can be seen that eliminating waste actually runs through various businesses. What we need is the eyes to discover waste and the execution power to eliminate waste.

The practical operation of on-site assembly of aluminum alloy frames has also deeply impressed us with the importance of standard operations. Otherwise, even with strong hands-on ability and no clear operation procedures and standards, there will still be waste of rework or repetitive operations.

Day 5 of Training: AVEX Visits and How to Deeply Import TPS Learning

AVEX is a highly automated enterprise that fully utilizes TPM. The company does not have dedicated maintenance personnel, relying on independent maintenance and rotating equipment maintenance every week to ensure that there are no malfunctions during normal times. In talent development, AVEX regards all employees as assets that can create value for the company, encourages them to do, learn, and try for themselves, and challenges everything. Every challenge is an opportunity for improvement, gradually reducing their dependence on external forces. Many of the customized fixtures seen on site are made in-house, which is a symbol of the success of talent cultivation in enterprises.

In the final TPS import learning, the teacher analyzed the on-site improvement bottleneck we proposed and provided solutions. We were required to prioritize the site and string up the problems one by one, so that we can more intuitively see the essence of the problem and solve it from the source.

In the final TPS import learning, the teacher analyzed the on-site improvement bottleneck we proposed and provided solutions. We were required to prioritize the site and string up the problems one by one, so that we can more intuitively see the essence of the problem and solve it from the source.

Although the five day journey of lean training has come to an end, the seeds of a new round of continuous improvement have just begun to sprout. We need to incorporate what we have seen, learned, and felt these days into our on-site work, continuously improving production methods that conform to the characteristics of Zhengcun. We believe that Zhengcun will continue to go further and better on the path of lean production.

Last article:Continuous Improvement of Canteen Management2023-09-11 16:53:07

Next article:File management upgrade2023-10-09 08:29:45