Effective methods to improve production efficiency

Release date:2023-07-17

Production efficiency is labor productivity, which is an important measure of the efficiency of a company's production resource utilization. Simply put, it refers to how many products can be produced by consuming similar costs in materials, labor, and production facilities.

The current market competition is becoming increasingly fierce, and the survival pressure of enterprises is increasing. In order to occupy a place in the fierce market competition, using scientific management methods to improve product quality, reduce resource waste, reduce production costs, and improve production efficiency is the key to enterprise survival. The pursuit of manufacturing enterprises is to maximize production efficiency and efficiency, and faster speed can meet the changing needs of the market.

Our company has been promoting cost reduction and efficiency improvement at the production and manufacturing site. In terms of efficiency improvement, according to the idea of Lean manufacturing, we identify waste in all aspects from different processes and different dimensions, analyze the products and processes with high inefficiencies in each workshop, develop an analysis, reporting and improvement mechanism for efficiency improvement, and focus on efficiency improvement, which is specifically reflected in the following aspects:

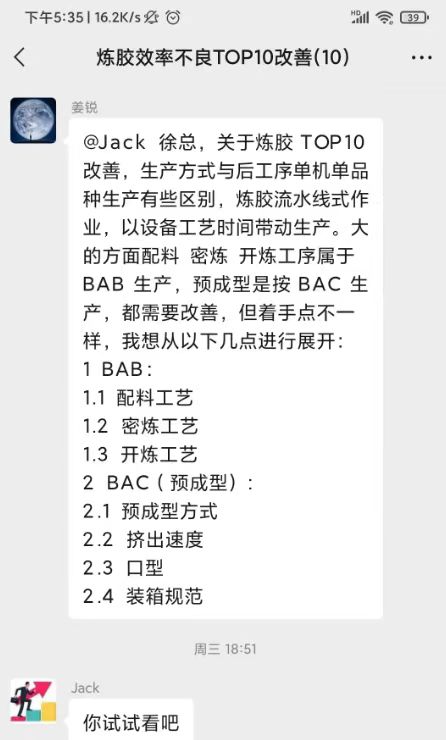

1、 Rubber mixing workshop

According to the production method of the rubber mixing workshop, the improvement of rubber mixing efficiency is analyzed into two modules: BAB and BAC (pre forming), among which the BAB module is divided into ingredient process, internal mixing process, and open mixing process; The BAC (pre forming) module is further divided into pre forming methods, extrusion speed, mouth shape, and packaging specifications. Analyze and identify waste from these different processes and dimensions, develop a top 10 for poor rubber refining efficiency, and focus on improving it.

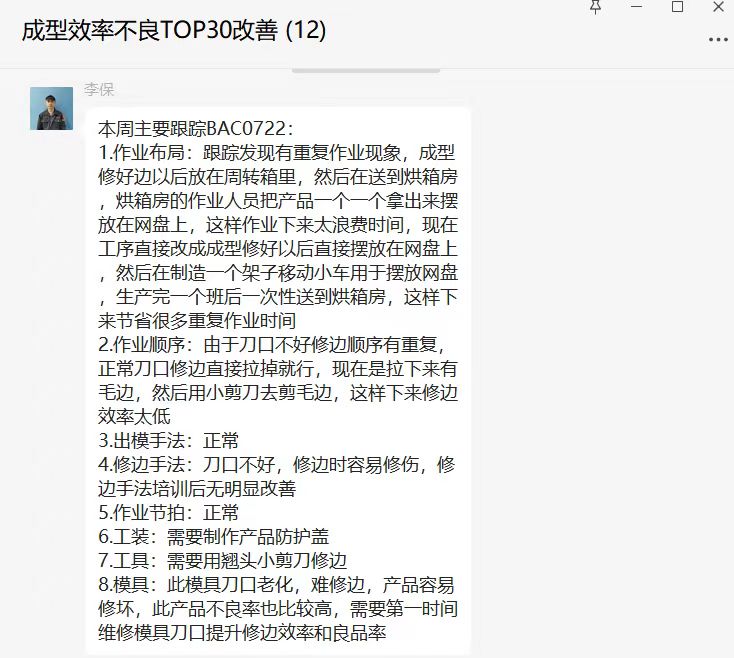

2、 Forming workshop

We identified and analyzed waste from eight aspects: homework layout, homework sequence, mold drawing techniques, trimming techniques, homework rhythm, tooling, tools, and molds, and developed a reporting and rectification mechanism for top 30 molding efficiency defects.

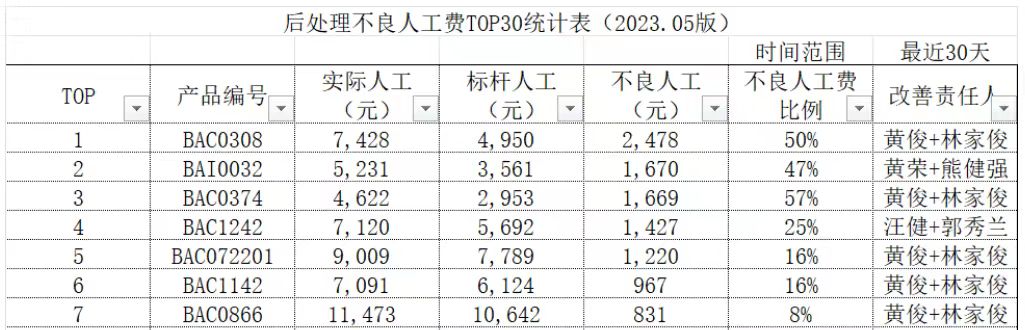

3、 Aftertreatment workshop

We conducted an analysis from six aspects: process route, operation sequence, operation rhythm, operation layout, packaging improvement, and pre process defects, and developed a reporting and rectification mechanism for the top 30 post processing time defects.

Based on the above analysis of waste, we have gained an understanding of the products and processes that waste the most time, and identified the root cause of the problem. Based on specific reasons, different rectification measures have been formulated, such as one person multiple machines, process merging (pressure repair inspection package merging), process splitting, mold inspection and maintenance, tooling improvement, and operation standardization, which effectively improve the production efficiency of each process in the company's workshops, enhance the company's product competitiveness, and lay a solid foundation for the company to complete delivery tasks with quality and quantity assurance.

Last article:Be an excellent quality engineer2023-07-17 08:51:04

Next article:Be a proactive person2023-06-04 00:00:00