Eliminate blind spots, eliminate dead spots--deep ploughing 5S

Release date:2022-09-06

The environmental sanitation of the factory is an intuitive reflection of the enterprise's 5S management level. It is not difficult to create a "clean, clear, and visualized" site in the early stage of 5S activities, but it is difficult to maintain it for a long time due to various factors. How to make 5S improve while maintaining and improving while improving is a big challenge.

Since the implementation of lean production in 2017, Shanghai Zhengcun has also adhered to the policy of continuous improvement in 5S management. For more than 5 years, the company has continuously strengthened the company's 5S culture through activities such as "One Weekly Scan" and "Equipment Fine Scanning". In the process, we also found that the definition of regional responsibility is ambiguous, and the dead corners of hygiene are ignored. In the recent stage, we have adopted new mechanisms and activities to make targeted improvements.

1. Establish a mechanism to check blind spots

The layout of the factory changes with the continuous development, and the 5S responsibility area that was previously divided will be ambiguous or unclear. For this reason, we have established a 5S responsibility division and update mechanism in the factory area. The new mechanism establishes the concept of 5S overall management in the whole plant, and comprehensively identifies buildings, area categories, area names, responsible departments and cleaning details, etc., and effectively finds out blind spots that are neglected or whose responsibilities are unclear. Timely adjustments and updates as needs change.

2. Self-exposure to eliminate dead ends

5S activities are like other daily work. After a long time, the top-down will produce paralyzing thinking, thinking that it is enough to see it in general, which leads to the generation of many sanitary blind spots, and the details cannot stand inspection at all. This phenomenon of only doing superficial work and not paying attention to detail execution is not only a damage to the 5S culture, but also an obstacle to the enterprise's serious spirit and continuous improvement policy.

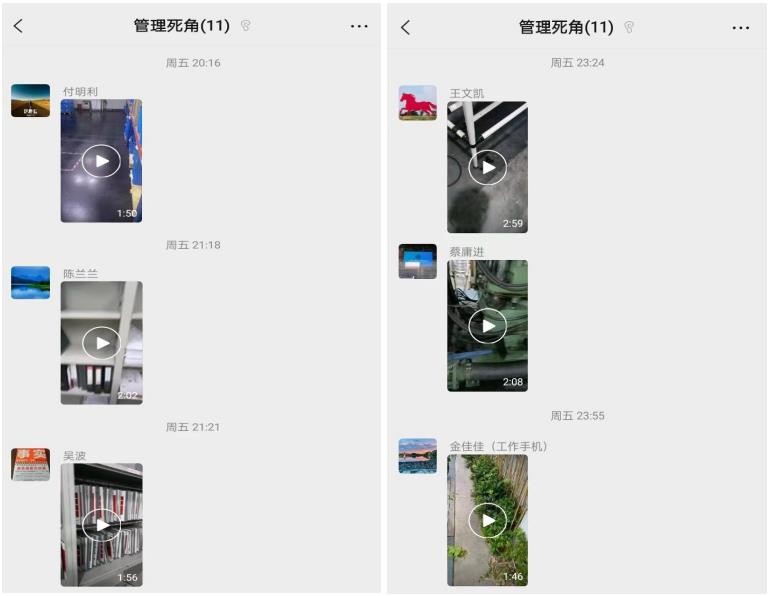

Recently, under the guidance and promotion of the company's superior leaders, we have specially established a sanitary dead corner management mechanism. The heads of each department will personally go to the site and work with their subordinates to self-expose and rectify the sanitary dead corners in the area of responsibility, and cooperate with each department. Share corrective actions and countermeasures. For the establishment and implementation of this mechanism, first of all, let the heads of various departments reshape the sense of 5S responsibility. The 5S activities are not just a show or just talk on paper, but to go to the scene to find and solve problems; Employee attention First, the superior should pay attention to it, solve the abnormality at the first time on the spot and educate and guide the employees, the enthusiasm and work quality of the employees will naturally improve; the last is to improve the management level. Effectively expand management vision and unify management thinking.

3. Bad news priority reporting

In our daily work, we are often used to reporting good news but not bad news, resulting in problems being covered up or not being solved immediately, and small problems have turned into major accidents. Toyota's concept of "Bad News First" has deeply inspired us. Only by exposing problems, solving them, and eliminating hidden dangers and abnormalities at the first time will lead to better work results. We have been advocating the habit of reporting bad news first at work. Exposing one's family scandal is not a shame, and raising an abnormality is not to make things difficult, but an honorable practice of self-correction and seeking change.

5S management is not a staged goal of an enterprise, but a permanent behavior of all personnel in the enterprise. We hope that through more effective activities and mechanisms, all employees will pay attention, participate, pay attention to details and take them seriously, and shape a 5S culture of sustainable improvement and progress.

Last article:Salary optimization, creating a win-win situation2022-08-22 08:51:27

Next article:None