Follow the trend and make inspection records paperless

Release date:2020-11-27

In the second half of 2019, the company introduced the latest SAP system, follow the company's continuous improvement and no waste management concept, quality management department members actively response, after more than a year of efforts, related to inspection all the paper records and standard of sorting and entry in the system, on-site inspection raw material incoming inspection to finished goods inspection, process inspection to the inspection of the finished goods warehouse by PDA scan code of the paperless management throughout the process.

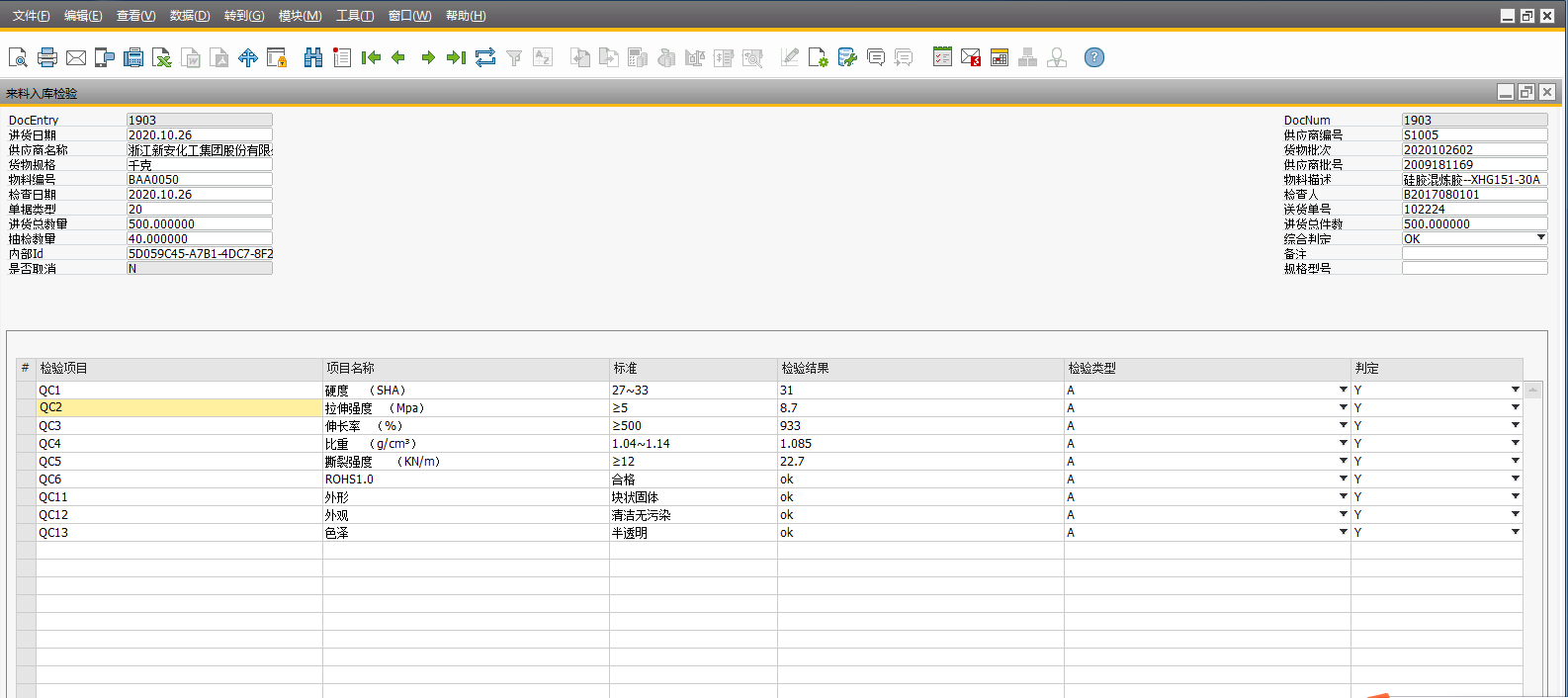

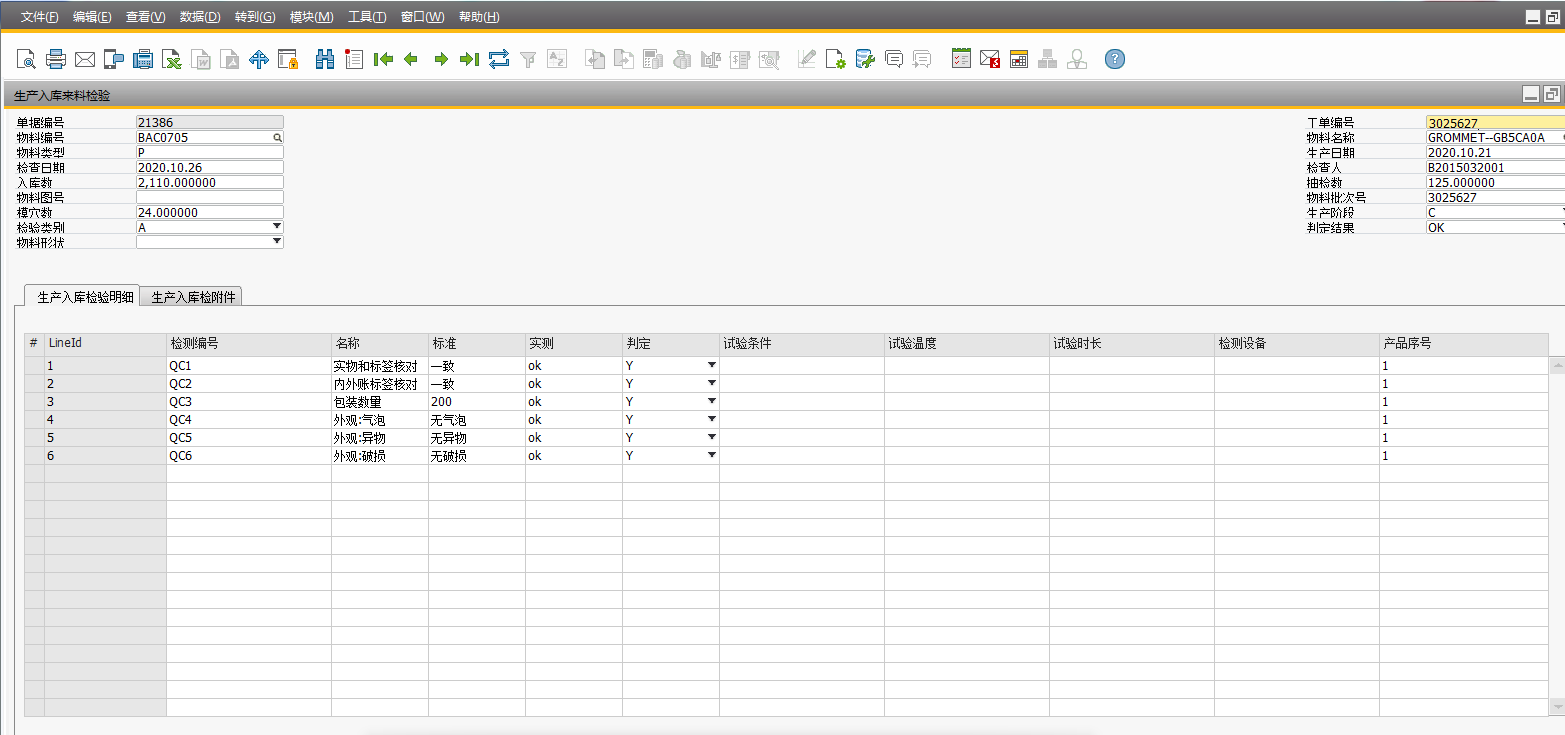

1. raw and auxiliary package incoming material inspection PDA scanning code

After the raw material comes in, the inspector inspects the material in the area to be inspected according to the warehouse entry list, scans the code through PDA, and directly inputs the inspection results into the system on site, and the system automatically determines that the material is qualified for storage.

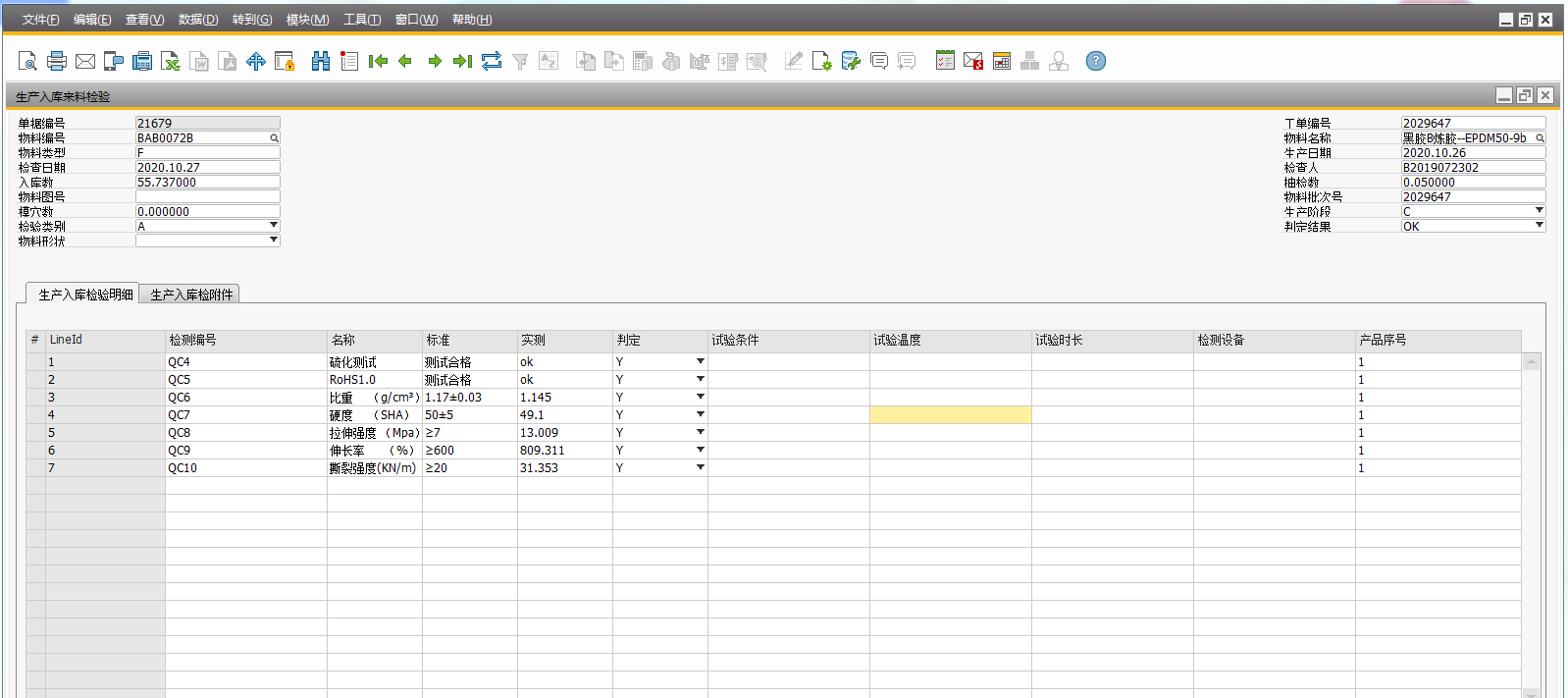

2. finished product inspection PDA scanning code

After the finished rubber material has passed the vulcanization quick test, ROSH test, hardness test, specific gravity test, tensile strength and tear strength test and other routine physical property tests, the inspector will scan the code through PAD, input the test results into the system and make automatic judgment, and mark and release after passing the judgment.

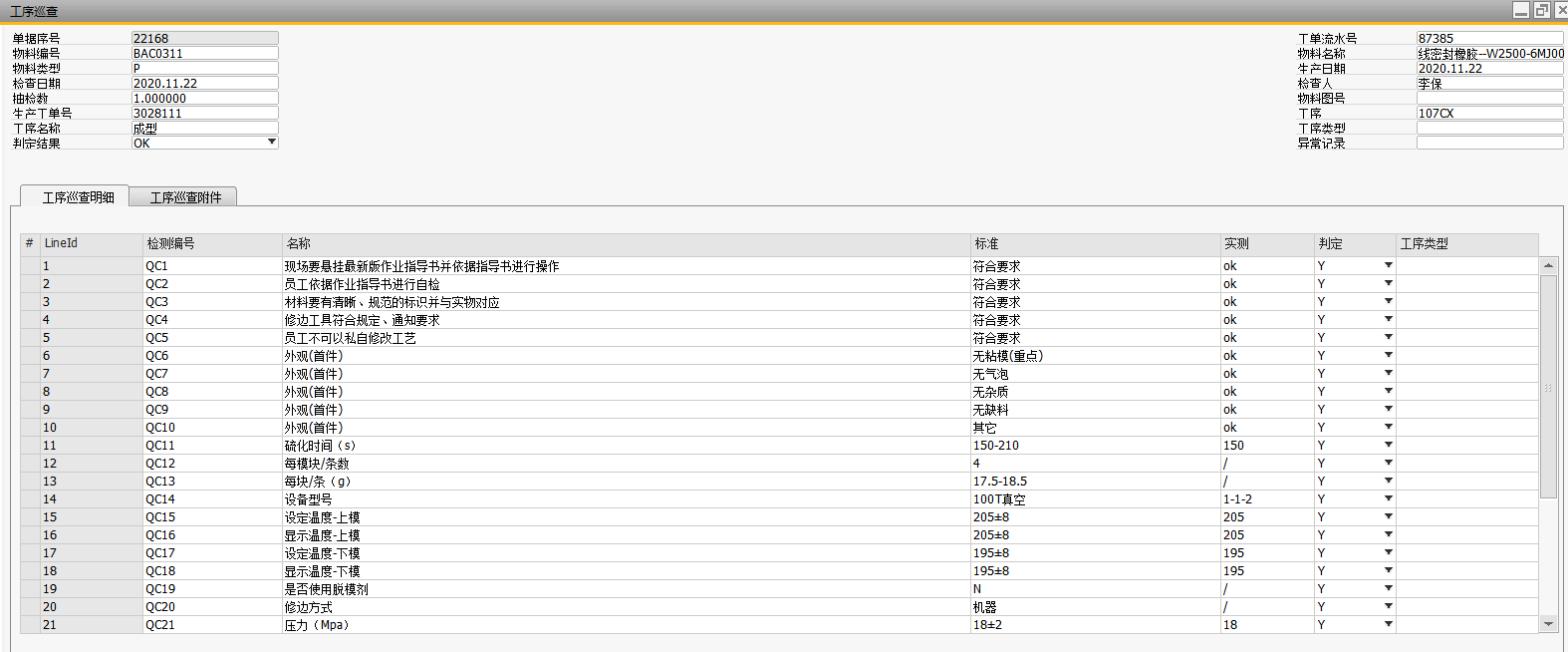

3. Process patrol PDA scanning code entry

Process inspection to check the process, product appearance, etc., through the PDA code scanning, on-site inspection results directly into the system.

4. PDA code scanning for warehousing inspection

Upon completion of sampling inspection of the products submitted for inspection, PDA code scanning is carried out to determine and sampling inspection results are input into the system.

The realization of paperless inspection records is of great significance to the quality control department, which has the most quality records of the company:

1. Paper records are changed into PDA scanning code input, which improves the work efficiency of on-site inspection staff.

2. Paper records are changed into electronic records, which saves the storage space and preservation time of records, and the archiving time is almost permanent

3. The improvement of paper records provides more convenient conditions for electronic records, the traceability of recorded contents and the use of recorded data for statistical analysis.

The electronic PDA of the inspection records provides more convenience for the process management of the quality control department, makes the daily work more efficient, allows the quality management to invest more time in the quality improvement and abnormal reduction work, provides support for the delivery of quality and inexpensive products to customers, and continuously improves customer satisfaction.

Last article:Kanban visual, let the management see2020-11-16 00:00:00

Next article:Lean supplier integration2020-12-10 00:00:00