TPS Learning in Japan

Release date:2018-07-20

——Participate in 284th Toyota Lean Benchmarking Training in Japan

Toyota Prodution System (TPS) has long been the source of core competitiveness and efficiency of Toyota. It has also become an example of international business management. Kanban management, as a major feature of Toyota's production management, has been adopted by enterprises all over the world. In order to actively promote Toyota's lean production model, the company organized staff training in Japan for four consecutive years. From June 10 to 17 this year, with the deepening of the company's lean production, we ushered in the fifth batch of study in Japan. Now let's show you the contents and results of our training.

First, the senior lecturer introduces himself.

Next is rich classroom learning.

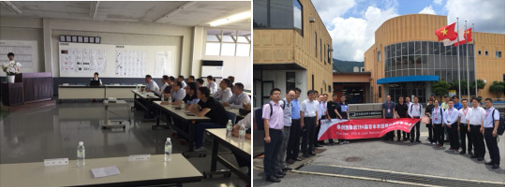

In addition to abundant classroom learning, we also visit the scene in the light of reality.

First stop: Kato Production Institute

Kato is the first-class supplier of Toyota interior decoration. We visited the production process on the spot in the factory. Mixed scheduling production is the deepest feeling of Kato's production. In order to meet the needs of customers (Toyota) on-site mixing line, Kato implemented counter-order production, delivering goods to Toyota every half an hour. In addition, the self-inspection of production process is also a bright spot.

In addition, Kanban management production mode was simulated and practiced in the field training room, and the understanding of implementing Kanban management JIT in Toyota was clearer.

Second stop: Akita Industrial Co., Ltd.

Akita Industry is a supplier of Toyota Seat Framework Material. Its internal automation level is very high, such as: automatic bending, automatic welding, multi-machine stamping line, compact production site layout, clear logistics route planning, stamping staff self-changing die, etc. All these reflect the excellent model of lean production factory.

Third stop: Nagoya Technological Research Institute

Independent R&D is powerful, technology is the guarantee and foundation. Perfect personnel training mechanism and strong technical support are the greatest harvest of Nagoya's technical research.

Fourth Station: Toyota Gaogang Assembly Plant

From accurate arrival control, reasonable on-line inventory, to accurate mixing line to second assembly, all reflect the extreme leanness.

Zhengcun has built a variety of platforms for the cultivation and promotion of employees'abilities. The company has organized employees to study in Japan for five consecutive years, so that we can deeply feel the essence of Toyota TPS. One batch after another of the company's promoters to improve the Zhengcun production model - ZPS gradually formed, developed and improved, effectively promoting the company to a broader space for development.

Last article:Talent is the most important in the development of company2018-06-25 00:00:00

Next article:Products display-Rubber Parts of Automotive Wire Harness2018-08-06 00:00:00